MDF(Midium Density Fiber) / HDF(High Density Fiber) are is made from forestry wastes (such as small wood logs, branches, sawdust, cutting wastes, barks, and etc) or agricultural wastes (such as sugar cane wastes, cotton stalk, and etc.). The fiber from the above mentioned wastes are mixed with adhesives, it will become qualified MDF/HDF panels (500-850 kg/m3) after a sery of processing procedures. The final products have tight and smooth surfaces and uniform structure in the core layer, meanwhile, the final products have good physical performance and mechanical processing potential.It's an ideal replacement of the natural wood panels. It's widely used in industries of furniture, decoration, packing, and etc.

According to the production technology, a complete MDF/HDF production line can be divided into the following sections: 1. raw material preparation; 2. refining and drying; 3. glue mixing, forming and pre-pressing; 4. hot pressing; 5.sanding and edge trimming; and etc.

After more than ten years of development, and our equipment and technology enable us to make products with high efficiency, good quality and low power consumption. Currently, we provide particle board production lines of 10000~90000 m3/year.

Some Related Parameters:

1.Capacity Range: 10000-90000 m3/year

2.Product Sizes: 4×8 ft, 6×8 ft, 6×9 ft

3.Hot Press Openings: 6-24 daylights

4.Product Thickness: 10-25mm

5.Product Density: 500-850kg/m3

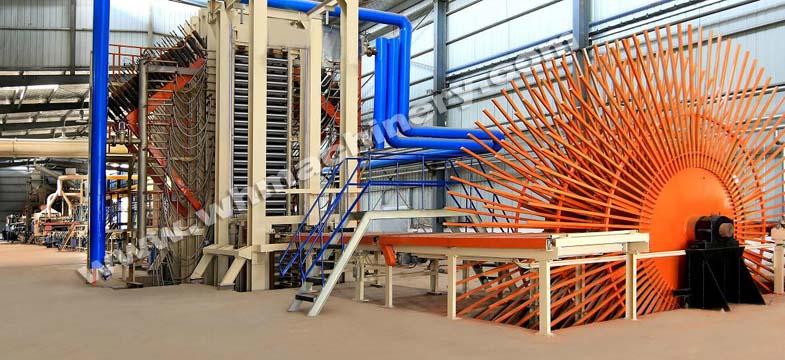

Pictures of MDF Production Lines:

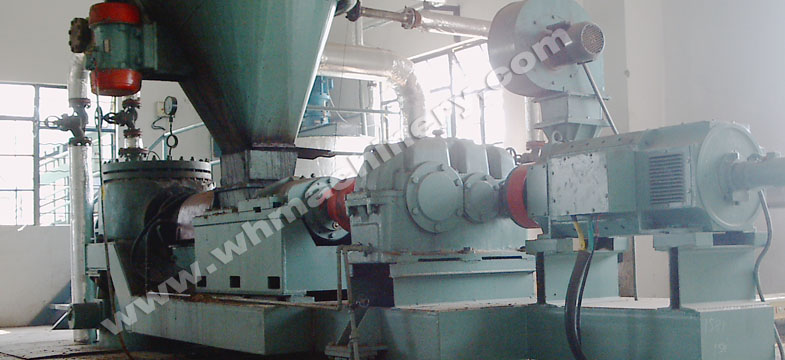

ParticleBoard Production Line

ParticleBoard Production Line